quality assurance

A key factor in our outstanding quality is the invaluable contribution of our employees. Their expertise, technical skills, and dependability are crucial for maintaining our high standards. This is further augmented by our continual investment in state-of-the-art production facilities and advanced measurement technologies.

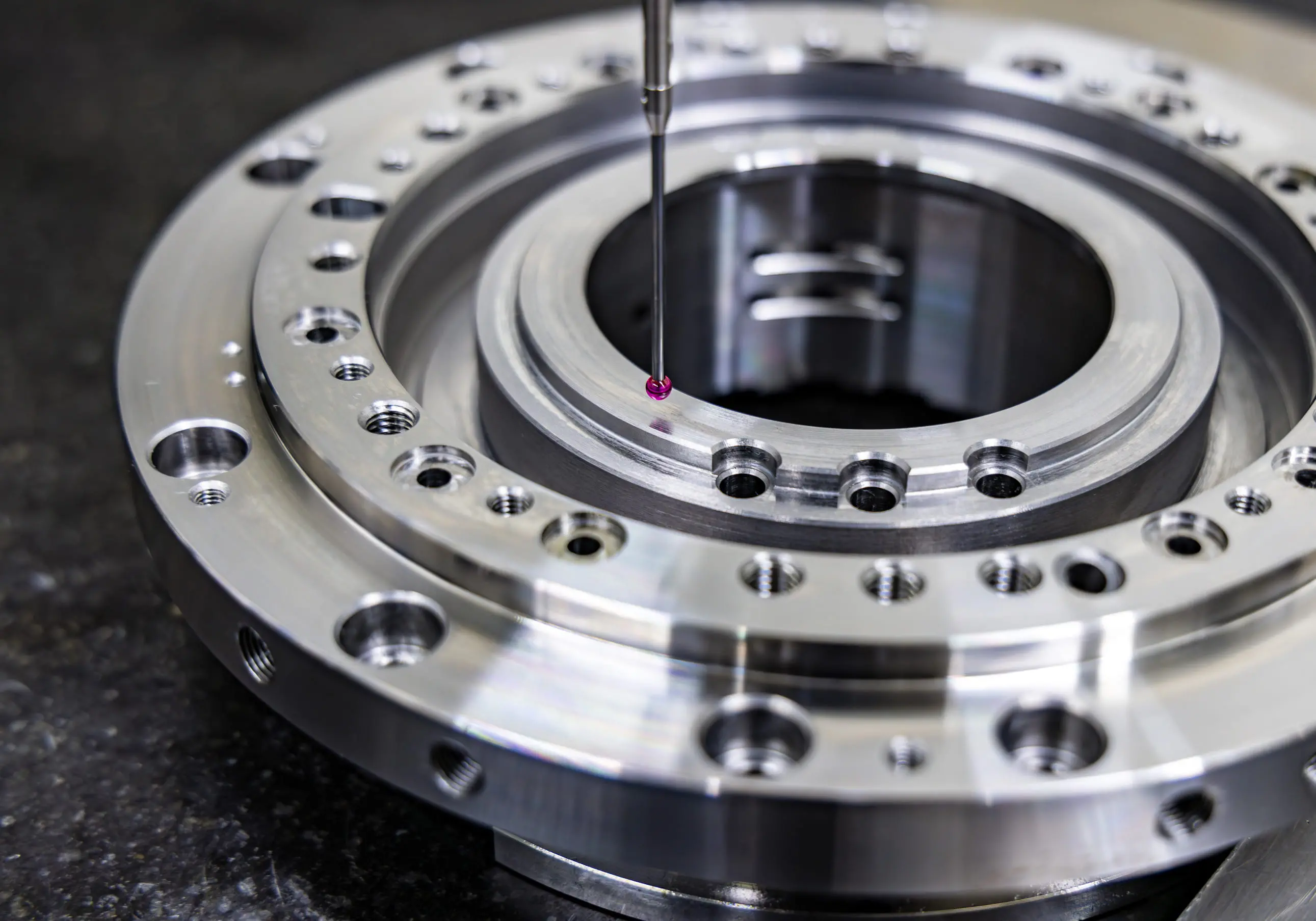

zero defect quality

We implement a zero-defect quality policy in our operations to guarantee uncompromised quality. A key element in achieving this is our employees' experience, technical skills, and reliability. We rigorously measure all geometric tolerances and variations, and can also accommodate specific measurement requests. For first-time products or prototypes, we conduct additional specialized inspections to ensure they meet our high standards.

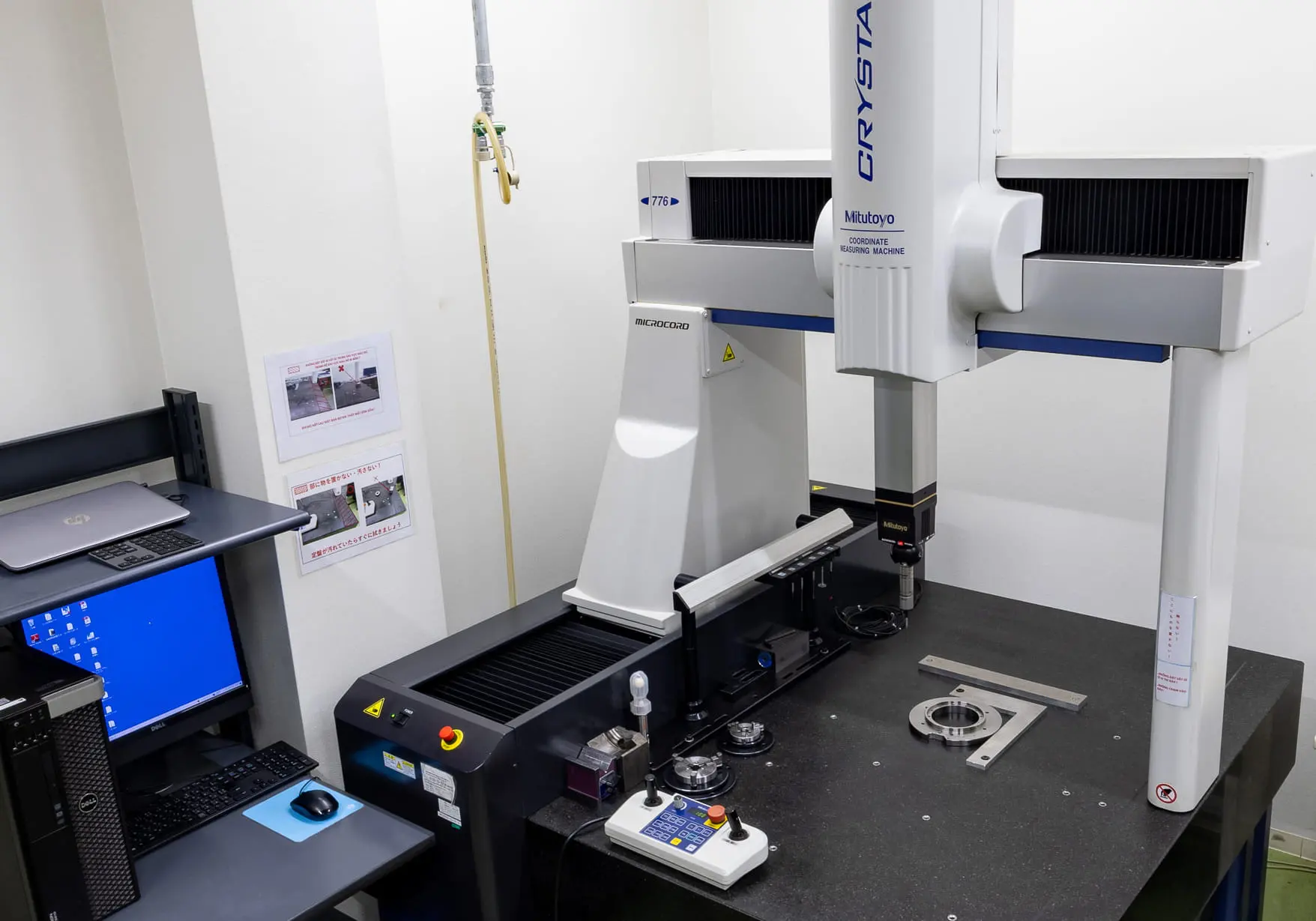

state- of-the-art equipment

We have the latest high-precision inspection equipment in a thermostatic room than can measure up to several micrometers. Roundness measurinhg machines, CMMs, hardness testing machines, surface roughness meters, etc. are available for all kinds of dimensional measurements, geometric tolerances, and mechanical properties.

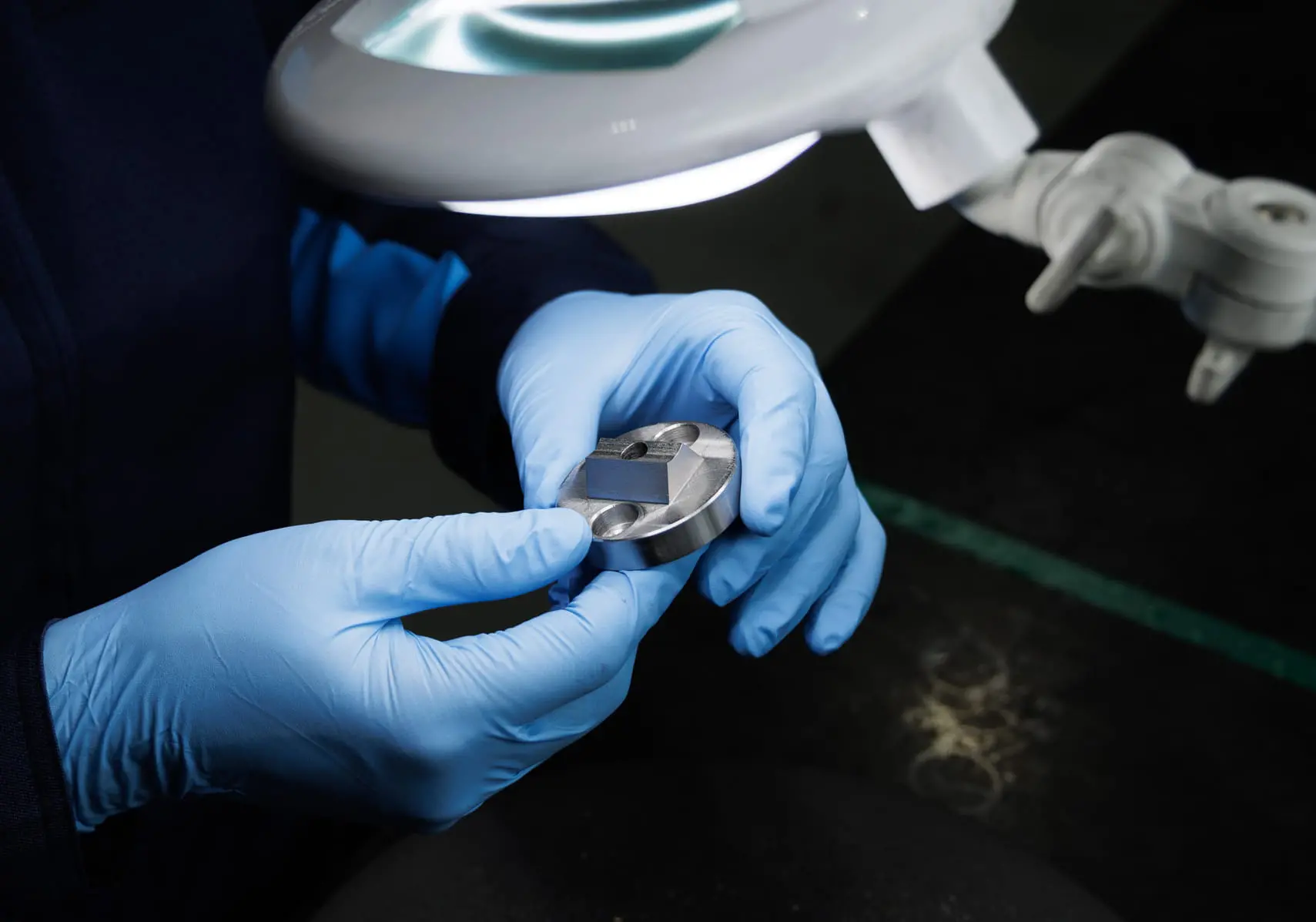

measurement technician

Advanced machine inspection technician from the National Skill Test of Japan(NTSTC) will carry out the measurements. Beyond just measuring, they are also equipped to provide advice on the suitability of machining techniques based on dimensional trends and surface conditions.

full traceability

The measurement data for each processed product is documented on an inspection certificate, which is included with the delivery. All this data is captured and managed in-house to guarantee traceability. Upon customer request, we can provide this data at any time and in any desired format.